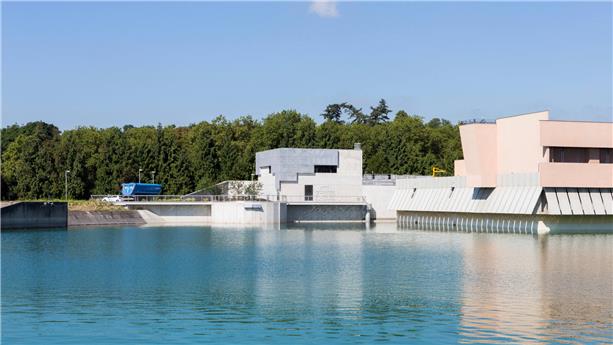

Aquadvanced plant

Manage the performance of your water and wastewater plants in real time and in 360° with Aquadvanced plant

Learn how the digital twin is revolutionising the management, design, and asset performance of water and wastewater treatment plants, significantly reducing operating costs and energy consumption. In an ever-changing world, our solution transforms decision-making through proactive intelligence and enhanced data management.

The complex management of water and wastewater treatment plants relies on precise knowledge of each piece of equipment and infrastructure. However, relying solely on data-driven decisions might not always capture real-life conditions, leading to longer interventions and less accurate maintenance plans. This is where the digital twin comes into play.

Imagine a solution that helps you visualise your treatment plant, understand its performance throughout its lifecycle, and predict how it will behave in different situations. By leveraging real-time data, it describes the current state of the treatment plant and enables predictions of its future condition.

With our digital twin, this vision becomes reality. In collaboration with industry experts, we have developed a revolutionary solution that transforms your treatment plant into a living digital model by combining asset digitalisation with artificial intelligence.

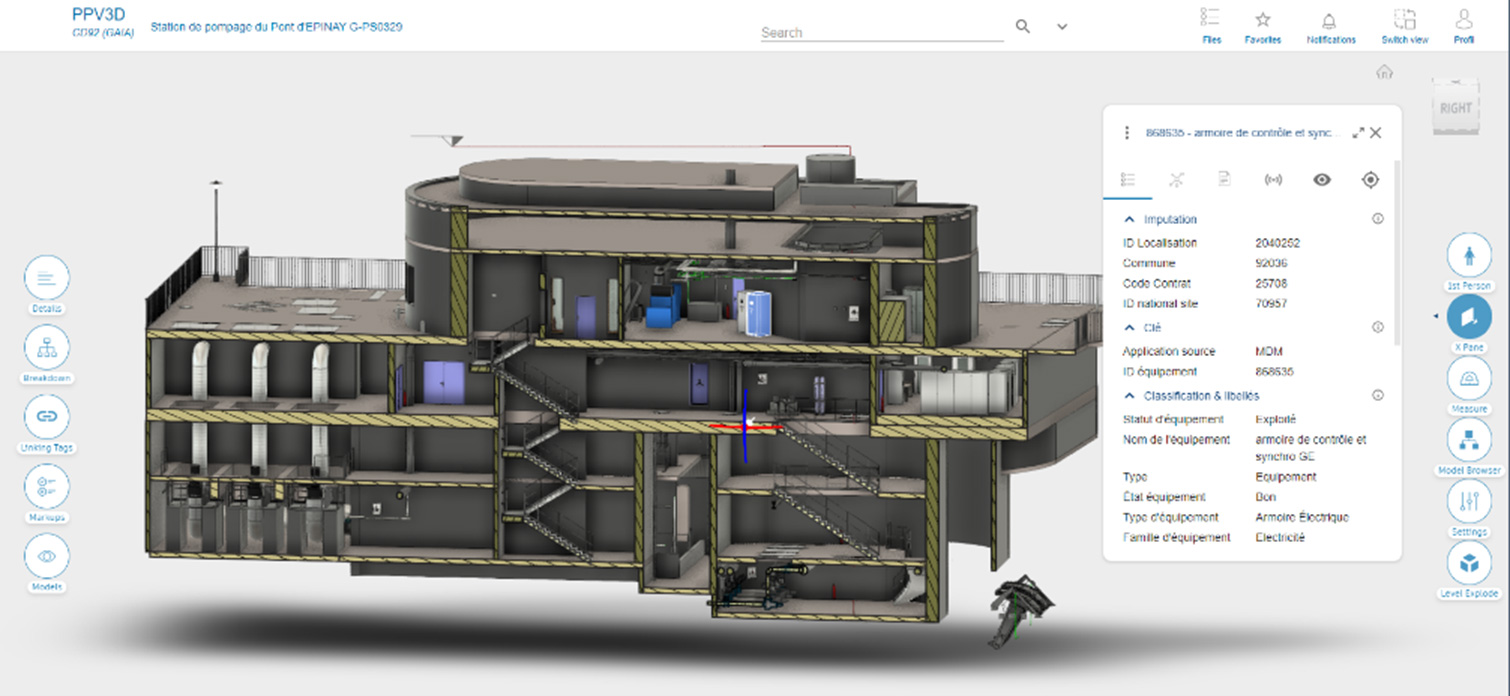

1. Digital representation of assets: Our digital twin integrates real-time data from various SCADA, sensor, IoT and other systems, ensuring a comprehensive and up-to-date representation of the infrastructure. In addition, our solution ensures smooth communication between different operating tools, such as CMMS and EDM. This integration provides operators with a realistic interface, allowing them to view the facilities as if they were on-site. But this digital model is not limited to visualisation. It facilitates a transparent exchange of information on assets, thus improving the safety of interventions and the training of operators. With this technology, teams can optimally prepare before going into the field, ensuring safer and more efficient operations.

2. Resilience: Our digital twin continuously assesses the state and operational health of the infrastructure through real-time monitoring. For instance, if sensors detect a rapid rise in a nearby river combined with intense rainfall predicted by weather services, the system identifies potential stress on the plant and triggers an alert. This enables plant operators to take preventive actions, such as activating additional pumps, closing valves to redirect flows, or reinforcing protective barriers, thereby preventing asset degradation. Additionally, the technology supports simulation exercises based on accurate models, allowing teams to test what-if scenarios, prepare for crises, and make informed decisions under pressure.

3. Prediction of behaviour: Our digital twin also enables advanced predictive analytics. By combining historical data with real-time sensor monitoring (such as power, flow, and pressure), it can predict the future condition of equipment, both functionally and structurally. For example, if a pump shows signs of gradual wear, the digital twin can predict when maintenance will be required, helping prevent unplanned breakdowns.

4. Decision optimisation: Using state-of-the-art optimisation functionalities, our digital twin allows managers to evaluate various “what-if” scenarios and select the best course of action to maximise performance while respecting constraints such as budget, environmental requirements, and operational limitations. For replacement and maintenance planning, the digital twin leverages Risk models to identify optimal mid- to long-term investment programs, helping optimise the life-cycle cost of assets.

In short, our solution provides powerful predictive and planning capabilities, enabling informed and effective decision-making in a complex environment.

Effective management of water infrastructure is essential to ensure the reliability and sustainability of water supply and wastewater treatment.

At SUEZ, we use digital twins to provide a comprehensive and personalised solution that transforms your asset management. With our expertise and advanced technologies, we help you anticipate, plan and optimise your operations and investment plans for a sustainable and prosperous future.

Trust us to reinvent the management of your water infrastructure with digital twins.

The digital twin is an accurate, virtual representation of a physical infrastructure that combines data and computer models.

It helps visualise a system, understand how it performs throughout its lifecycle, and predict how it will perform in different situations. Using real-time data, it describes the current state of the system and allows predictions of its future state. In short, the digital twin facilitates decision-making to optimise the performance of physical infrastructures.

Digital twins and digital mockups are both detailed digital models of an object, process, or physical environment. Digital twins are designed to simulate and analyse the behaviour of a system in different situations, while digital mockups are primarily used for visualisation and representation of a system.

BIM (Building Information Modelling) is a digital modelling process that allows buildings to be designed, constructed, and managed collaboratively throughout their lifecycle. It provides an integrated and shared view of project data.

Unlike BIM, which is a modelling process for building design and management, the digital twin is a real-time virtual representation of a physical object used for its operation and maintenance.

To set up a 3D digital twin, you first need to collect data about the physical object to be modelled and then create a virtual representation using 3D modelling software. This representation should be enriched with real-time data from sensors and other sources to accurately reflect the state and behaviour of the physical object. Finally, it is necessary to set up an IT platform capable of processing and analysing this data to enable effective management and informed decision-making.

The different types of digital twins include network, treatment facilities, city, and construction, each of which is tailored to specific applications in fields such as industry, urban planning, and more.

Digital twins, which combine simulations and system models, are essential technological tools for optimising processes in a water or wastewater treatment plant. By combining simulations and system models into a digital twin, engineers can create accurate virtual representations of the plant, allowing for testing and simulating different scenarios. This approach provides an in-depth understanding of system behaviour, helping to identify inefficiencies and optimise processes to improve operational efficiency. By integrating real-time data from equipment into digital twins, operators can monitor and adjust performance in real-time, ensuring optimal plant operation.