SUEZ Awarded a Sludge Dewatering Contract in Hong Kong, Setting a New Benchmark for Asia’s Largest Sewage Treatment Plant in Caverns

- SUEZ has been awarded the contract for supplying sludge dewatering solution for the Relocation of Sha Tin Sewage Treatment Works to Caverns by the Drainage Services Department (DSD) of Hong Kong SAR Government. The project will be delivered by SUEZ, leveraging a sludge dewatering technology developed and continuously improved over more than 15 years through SUEZ’s collaboration with Bucher Unipektin AG.

- This sludge dewatering contract covers design, equipment supply and delivery for the new Sha Tin Cavern Sewage Treatment Works (STCSTW).

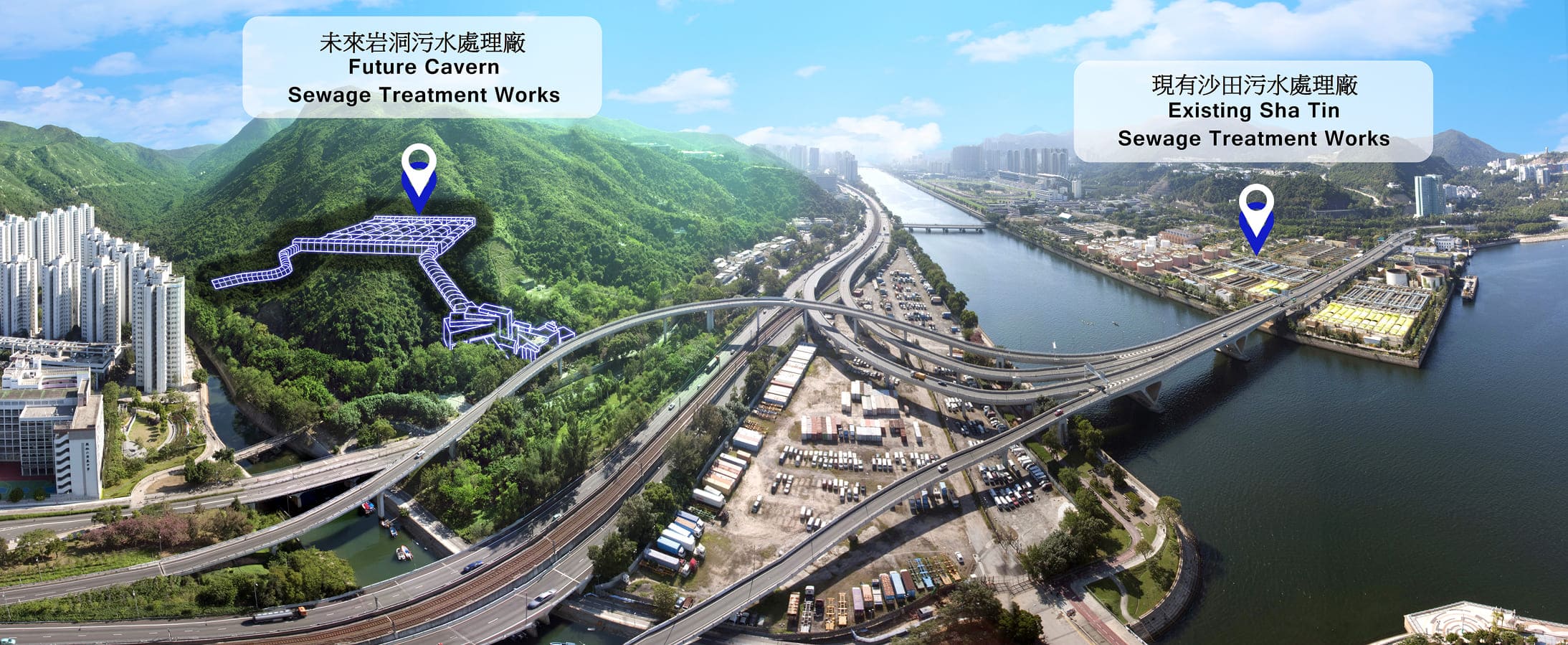

- Scheduled for completion in 2030, the new facility is set to become one of Asia’s largest sewage treatment plants built inside an artificial cave. With its compact design and advanced process standards, the STCSTW will optimise land use and set a new benchmark for sustainable, green infrastructure in Hong Kong.

New cavern-based wastewater facility to support sanitation needs and relieve land pressure

The existing Sha Tin Sewage Treatment Works has served approximately 700,000 residents for over 40 years. As the facility needed modernisation works, the DSD has decided not only to address the challenge of aging facilities, but also to tackle the acute land scarcity issue and to improve surrounding community environment.

The DSD initiated the relocation of the Sha Tin Sewage Treatment Works into a purpose-built cavern, comprising a 14-hectare site and an upstream sewage collection system. This strategic move allows major benefits for the Hong Kong population:

- It will limit olfactory nuisance as caverns act as natural barriers that contain and attenuate odours. Furthermore, inside the cavern, odour sources will be enclosed and dedicated deodourisation facilities will be installed.

- It will free up 28 hectares of surface land for other beneficial uses.

Long-term technology collaboration between SUEZ and Bucher Unipektin AG supporting cavern operations in Hong Kong

Recognising the constraints of cavern-based facilities, including limited space, controlled access and strict safety requirements, SUEZ will equip the project with 16 units of its proven Dehydris™ Twist sludge dewatering system. Fully enclosed and highly automated, this system supports safer operations in confined areas and helps reduce operator exposure. Its compact design reduces footprint by 25% and offers greater flexibility to allocate other essential equipment within the caverns.

Dehydris™ Twist sludge dewatering solution has proven to be stable and reliable across SUEZ projects in France, Italy, Australia, and the Chinese Mainland.

In Hong Kong, seawater flushing for about 85% of the population increases sewage salinity, typically reported around 5,000 - 6,000 mg/L, which can influence dewatering performance. To confirm results under local conditions, Dehydris™ Twist was piloted in Hong Kong for several years.

The trials showed consistent performance, raising sludge solid from around 3% to no less than 30%, reducing sludge volume and associated transport and disposal costs.

The system is expected to produce about 120,000 tonnes of dewatered sludge annually, supporting energy recovery and Hong Kong’s circularity and carbon reduction goals.

Commenting on the long-term technology collaboration supporting this project, Daniel Schneider, CEO Bucher Unipektin AG, said: “The implementation of Bucher HPS Technology at the new STCSTW as part of the SUEZ Dehydris™ Twist workshop marks a significant milestone in acknowledging the growing need for advanced biosolids dewatering solutions. Our technology sets new standards in efficiency and sustainability, demonstrating what is now achievable in modern wastewater treatment. There is no doubt that this innovation will play a pivotal role in supporting sustainable and economically efficient development, both in the rapidly expanding markets of Southeast Asia and across the rest of the world.

”

.jpg?w=730&v=1&d=20260129T161323Z&format=jpg&crop=0&hash=FE211A23F98ABEE0D08F5B3137A3D96E)