Waste Advanced allows users to adjust the management actions of the units they are in charge of, with the guarantee of a better stability of the whole process. Thanks to the global vision it offers and the predictive analyses, the intelligent platform makes it possible to anticipate anomalies and reduce hazards. Thus, interventions for dispensable curative maintenance actions are reduced, and preventive and predictive operations are better prepared and optimized. With more anticipation, it is now possible to control performance, reduce maintenance costs and reagent consumption.

Image Generic

Image Generic

Advantages

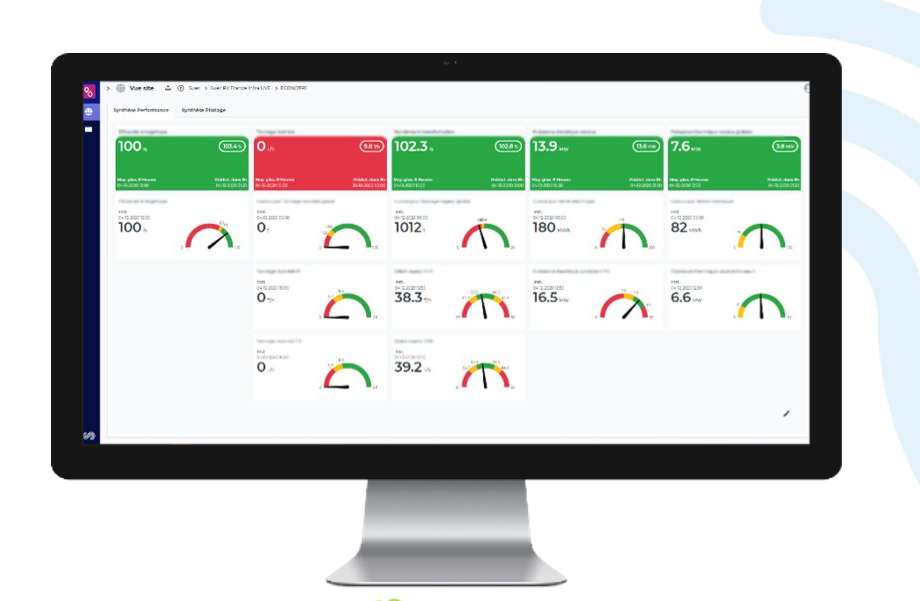

Real-time performance hypervision

- Valuation of data in performance indicators

- Global and centralized vision of these indicators for a park of EFW plants

- Customizable platform that can be accessed at any time

Economic and operational performance

- Optimization and stabilization of processes (combustion, energy production, flue gas treatment)

- Optimal use of equipment reactive interventions

- Development of action plans to improve overall performance

- Easier analysis of the effectiveness of the strategies implemented

Anticipation of malfunctions and drifts

- Automatic detection and anticipation of malfunctions and drifts (turbine vibration/overheating, irregular furnace filling rate, overconsumption of reagents and energy, etc.)

- Decision support for operational staff and management

- Safety of the installations

Features

- Real-time dashboard with visualization of the 6 key performance indicators

- Customizable dashboards by the user

- Detailed dashboards (analysis, history, management...)

- Regulatory reporting on discharge quality

- Detection: vibration/overheating of turbine, overconsumption of feed water, bad draught, insufficient homogenization of waste, irregular rate of furnace filling, deviation of air condenser vacuum setpoint, etc.

- Anticipation: boiler & exchanger leakage/clogging, overconsumption of reagents and energy, line stoppage, turbine trip/breakage...

- Predictive maintenance