SUEZ and Humens join forces to build a power plant that uses solid recovered fuel (SRF) instead of coal

What is solid recovered fuel?

SRF is an alternative fuel made from non-hazardous waste produced by businesses and individuals. The waste is recovered from waste collection sites or directly from businesses, and is first sorted to remove any recyclable items. The remainder is then shredded and converted into heat, which is used to produce chemicals and agrochemicals, instead of burning gas or coal.

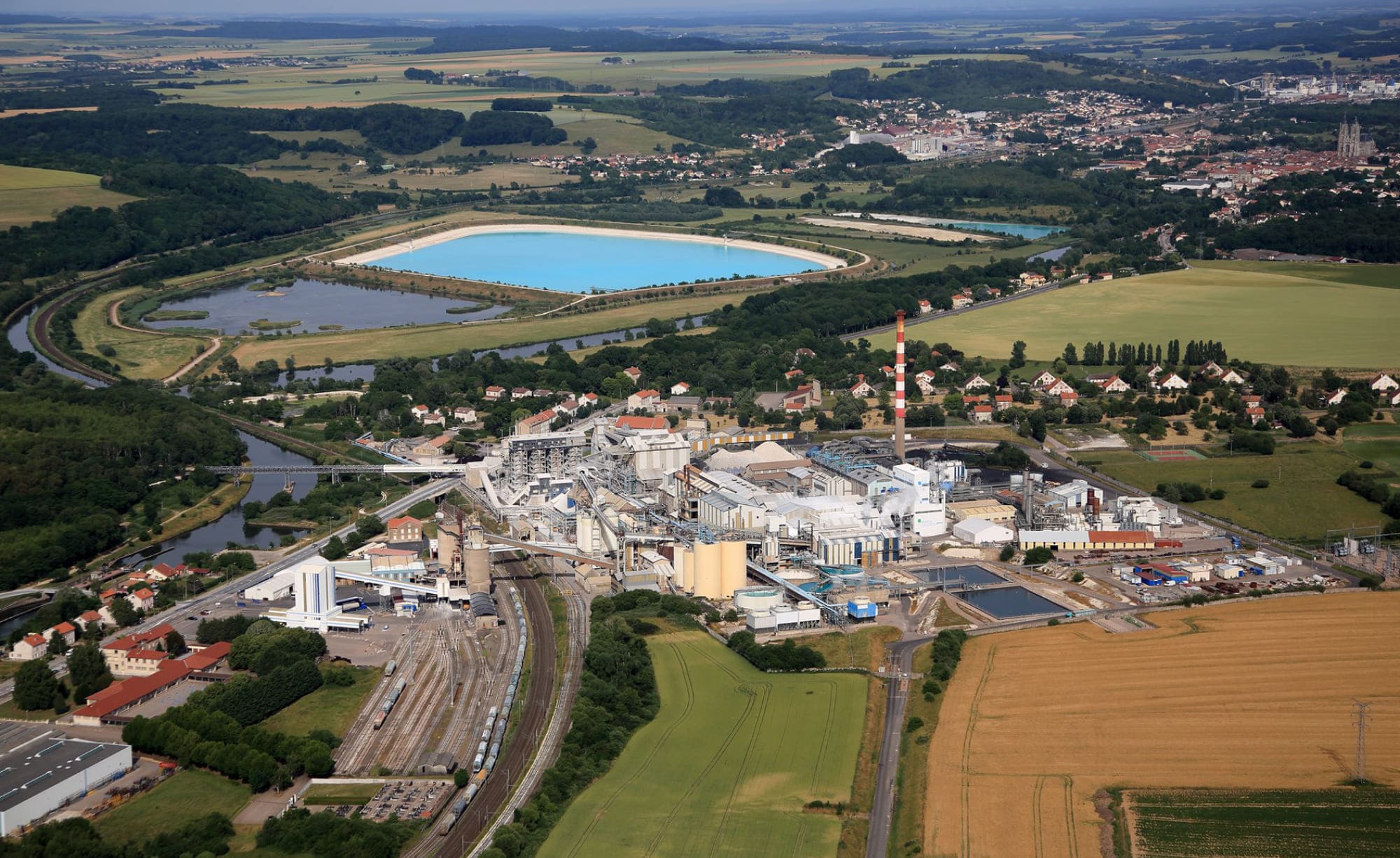

As a partner in this project, SUEZ is responsible for the design, construction and operation of Novasteam’s facilities. Construction started in summer 2023 and will continue until 2025. The first SRF batches are expected in the fourth quarter of 2025, and the energy recovery unit is expected to be operational before the end of 2025.

Building a local SRF collection and recovery network

As a leading provider of circular waste solutions, SUEZ will set up a local network to supply the site with SRF. The network will include the collection, aggregation and pre-sorting of raw waste, and the resulting material will be transferred to the Novasteam plant for processing and conversion into heat. Each year, 140,000 tonnes of waste with a high energy content, such as waste from economic activities and municipal waste (bulky waste, recycling rejects) will be recovered and used by the network.

Ensuring the site’s future viability, safeguarding and creating jobs

The construction and operation of the Novasteam plant will have a long-term positive impact on employment in the Nancy region:

- 150 people will be involved in the construction of the two units preparing SRF and converting it into energy;

- around 40 direct jobs will be created to operate the SRF preparation network and the heat generation unit;

- 300 direct manufacturing jobs and 150 indirect jobs at the Novacarb site will be safeguarded by maintaining the site’s competitiveness in the long term;

- The industrial network around the Madeleine plant and its quarry in Pagny-sur-Meuse, along with the development of the local SRF network, also represent a large number of indirect jobs.

Supporting the Région Grand Est’s energy transition targets

This circular economy project is helping the Région Grand Est achieve the targets of its regional waste prevention and management plan (PRPGD):

- 20% reduction in the amount of waste stored (reduction of 716,000 tonnes by 2031),

- 20% increase in the region’s capacity to generate energy from waste from economic activities (increase of 500,000 tonnes by 2031).

.Raymond Sinnah, Chair of the Humens group,” said Novasteam represents a major step forward in our industrial decarbonization efforts, which we have been pursuing for several years. By diversifying the energy mix of our Novacarb production site, we are making it more sustainable. We are also proud to be working with partners committed to sustainability and with strong local roots, thereby contributing to the region’s economic momentum“