On site assessment

of emissions (odours, pollutants and their source*), study of regulatory requirements of definition of emission reduction plans

A comprehensive assessment of emissions allows us to identify the most relevant sources and design an action plan to minimise the impact of the facilities. Usually, these studies must be approached through different strategies to accurately diagnose the problem: Olfactometry studies (based on UNE-EN-13725, UNE-EN-16841 standards), chemical speciation of VOCs through active and passive samplers, on-line detection through nano sensors, greenhouse gas emissions, detection of fugitive emissions through infra-red detectors, among others.

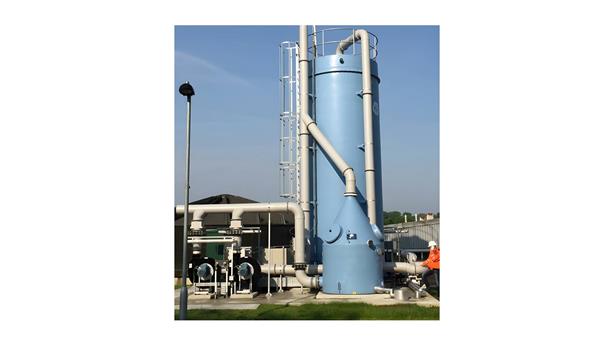

Considered the Best Available Technology (BAT) for treating odorous emissions, where final odour concentrations of less than 500 uoE/m3-1.000 uoE/m3 can typically be achieved, which ensures compliance with the strictest odour emission limits.

Thanks to the inoculation of specific microorganisms in the advanced biomedia, it has the capacity to simultaneously purify nitrogen compounds, sulphur compounds and VOCs.

Innovative solution for the treatment of odorous compounds from surface sources, such as H2S and VOCs as well as greenhouse gases such as N2O.

Main benefits: low-maintenance technology that removes a wide range of pollutants with efficiencies up to 80% and consumes no energy. A cost-effective and sustainable option.

Business sector addressed: Waste and Water facilities, Food & Beverage, etc.

A plug-and-play solution based on Advanced Biofiltration which treats odour and H2S (small/medium flowrates).

Highly efficient system in treating emissions with a high presence of hydrogen sulfide (H2S) and odours (small/medium flowrates). It can also purify other Volatile Organic Compounds (VOCs) and it does not produce harmful byproducts, making it a more environmentally friendly option

Covering technology that uses hexagonal-shaped floating pieces, providing a robust, economical, sustainable and long-lasting solution, without the need for additional treatment.

A system that efficiently purifies gases contaminated with Volatile Organic Compounds (VOCs) and other odorous substances.

Treatment unit for VOCs, odours, noxious and corrosive gases.

SUEZ Testimonials: Advanced biofiltration at Planta de Biometanizacion Las Dehesas - SUEZ

Credit: SUEZ group

*regulatory requirements, impact studies and emissions reduction action plan

** such as photocatalysis, adsorption, condensation, biofiltration, thermal oxidation or chemical absorption