To attain our “Zero severe and fatal accident” goal, and create an integrated Health and Safety culture, we have initiated and continues to deploy a Health and Safety policy based on three areas:

- A shared awareness of our risks and how to avoid accidents

- Committed employees for a proactive, participative and fair Health & Safety culture;

- Training to develop Health & Safety behaviour.

We share our ambition for a strong Health & Safety culture with all our subcontractors, suppliers and customers, and beyond our own activities. As a member of the ICSI institute for an industrial safety culture, we participate in workgroups and help to develop tools for other companies and public authorities that share our ambition to improve the Health & Safety culture.

Managing our major risks - Objective of zero severe and fatal accidents

- The standards cover our major business risks so that in each of our activities, all prevention and protection measures are implemented at the very heart of our operations and that the means to avoid accidents are known and respected by all.

- The "10 rules that save" are the latest individual prevention barriers applicable to all our activities. Anyone who may be exposed to our major risks is regularly trained in these rules which, if followed, save lives. The aim is to raise individual and collective awareness of our most important risks, including with our subcontractors and customers, to change behaviors on a daily basis so that we can work in complete safety. Multi-year actions have been taken to control each major risk in our activities. They are based on the three pillars of an integrated Health & Safety culture (Technical, Management System and Human and Organizational Factors) while implementing innovative solutions.

10 essential rules for working safely | Life-saving rules | SUEZ

Credit: SUEZ group

Our life saving rules

- Detailed risk analyses regularly are carried out for our activities, throughout the world. Operational risk control is assured, and additional controls can be deployed where necessary. Regular audits enable us to manage and control our major risks.

- We encourage internal and external innovations that could improve work conditions and have a positive impact on Health & Safety for everyone. All this Experience Feedback is shared via the Innovation Trophies event and during good practice exchanges between entities. The detailed event analyses are also shared.

Committed managers for a proactive Health & Safety culture

- They collaborate with the teams in the field to deploy technical, organizational and human improvement actions,

- They make sure that the working environments are healthy and safe,

- They regularly hold team meetings to allow all employees to contribute to the improvement actions and commit to safe conduct to improve Health & Safety for everyone,

- They also conduct Managerial Safety Inspections of work situations and promote good conduct,

- They ensure regular monitoring of the action plans related to reported events and focus on those that could potentially be very severe.

Developing a participative health and safety culture

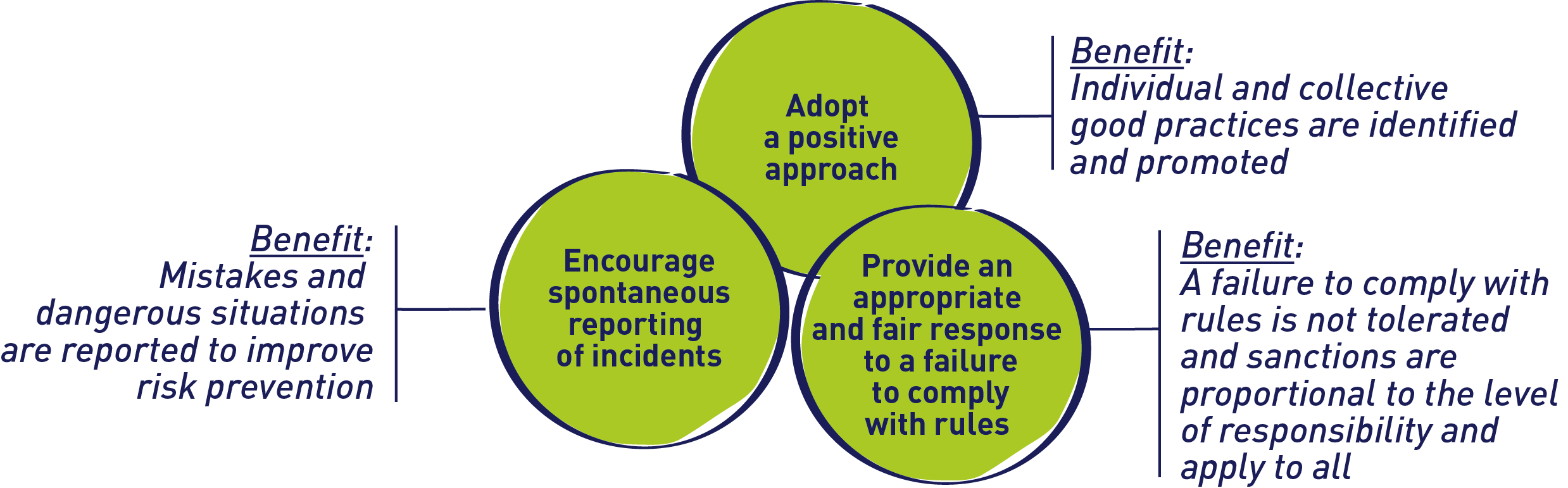

With this in mind, we launched “Fair Culture” in 2014, an initiative aimed at creating a climate of trust within the teams, thus encouraging more transparency and sharing to strengthen risk prevention.

Fair Culture is based on three pillars:

- Good practices and good conduct are promoted so that each and every person is aware of what is expected and encouraged to do it.

- Hazardous situations, notably those that could potentially be very severe, are reported, analysed and shared within the group to enable the implementation of risk control measures to prevent re-occurence.

- Errors are analysed and treated as improvement opportunities to help understand the factors that resulted in a hazardous situation and for future prevention.

- Discipline related to transgressions of the rules is proportional to the degree of individual and collective responsibility and apply to everybody.

In 2024, to further the deployment of Fair Culture and Life Saving Rules, we launched the Speak Up & Stop! campaign. Everyone is entitled and required to say "Stop!" when they see a situation that seems dangerous, and particularly when a Rule That Saves is not respected.

Every decision matters | Speak Up & Stop ! | SUEZ

Credit: SUEZ group

Training to change behaviour

“Safety Always”: At SUEZ, safety is everywhere, anytime, with everyone and for everyone.

- All our managers benefit from an initial two-day structuring training course, which is the foundation of SUEZ's Shared Health & Safety Culture. Regular refresher courses are also organised in the form of digital content or face-to-face training.

- The SUEZ Academy also offers on-line courses on Human and Organisational Factors, designed in partnership with the ICSI* Safety Academy, for its managers and prevention agents.

- The Health & Safety staff receives specific expertise training in order to continuously develop its skills. In addition, prevention agents are trained in "influential leadership" to develop an efficient partnership with operational management, in order to build a strong Health & Safety culture with employees in the field.

- We have developed virtual reality modules on the major risks of our activities which are starting to be deployed in our different entities. In a realistic virtual environment, employees are thus confronted with everyday dangerous situations in total safety. The virtual simulation of their working environment gives them a better understanding of the required actions and the appropriate responses to avoid accidents.

“Job” training courses are carried out within our entities for all new hires and all employees receive regular refresher training to update their knowledge.

*ICSI: Institut pour une Culture de Sécurité Industrielle (institute for an industrial safety culture), non-profit association founded in 2003

Group Health & Safety policy