COVs

Leaks origin

90% of the reducible emissions come from approximately 0.1% of the components and process equipment (flanges, valves, pumps, storage tanks, etc.) what are called large leaks.

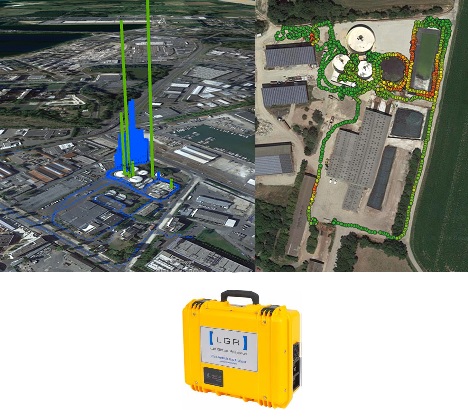

Features of our SCAN360 system

Our system is based on an LWIR bispectral camera, which allows the capture of complete information, including the thermographic analysis of the facilities for the detection of failures and process optimization, and the detection of fugitive emissions through IR video recording. The georeferencing of the images and their co-registration with a visible image, enhance the details of the inspection and the precise identification of the affected components.

The system is completed by detailed analysis in the cabinet for the automatic detection of fugitive emissions and their quantification (ppm.m), optimizing the times of the review by an expert technician.

This technology is supported by the services that we currently offer for the detection and quantification of fugitive emissions using manual FID or PID sniffers included in LDAR programs.

Advantages

The flexibility, of our dual-use technology, allows it to be shipped on a drone to cover large areas or used directly by a field inspector for more precise work, having maximum accessibility to all industrial areas.

- Drones, with their load capacity, can move different types of sensors, carrying out multiple types of work and adaptations to each environment and need, providing high value to services.

- Safety: The services offered reduce the risks of accidents associated to inspection and control tasks in areas that of difficult access or that represent a danger to people.

- Technology recognized as BAT for the identification of fugitive emissions according to the BREF documents.

SCAN 360 Quick-Scan