The issue

Wessex Water approached SUEZ to carry out Ice Pigging™ at three Sewage Pumping Station (SPS) sites where the suspected buildup of deposits in the rising main had been causing low flow rates. Each rising main was small in diameter, at DN50 or below.

Due to the small diameters, very few options are available for cleaning the entire length of the main. A vacuum tanker had been attached to alternately vacuum and flushed a short section of the pipe at some locations, but any improvement gained had been temporary.

The solution

Ice Pigging™ was applied at all sites without requiring any permanent enabling works. Ice insertions took place via an existing Bauer connection or by adapting a fitting at the SPS. An Air Valve at the halfway point of Site 2 was utilised as a breakpoint, though it would also have been possible to clean the entire section in a single operation.

We were really pleased with the results of these operations; the flow increases at each site means that we no longer need to run tankers from these stations during bad weather. We are sure that this technique will be useful at a number of our other sites.Ashley Pratt , Wessex Water

Ice Pigging™ Wastewater Pipe Flow Improvements

The results

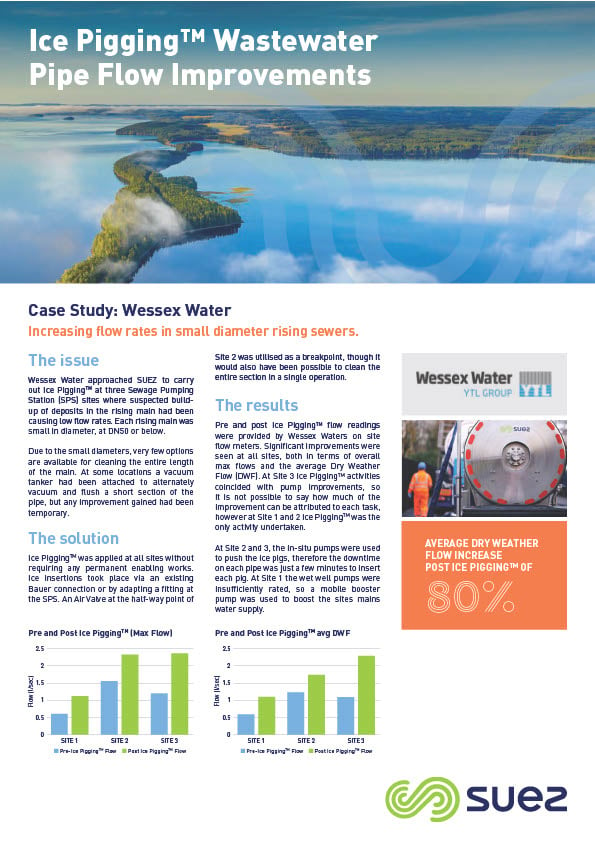

Pre and post Ice Pigging™ flow readings were provided by Wessex Waters on-site flow meters. Significant improvements were seen at all sites in terms of overall max flows and the average Dry Weather Flow (DWF). At Site 3, Ice PiggingTM activities coincided with pump improvements, so it is impossible to say how much improvement can be attributed to each task; however, at Site 1 and 2, Ice Pigging™ was the only activity undertaken.

At Site 2 and 3, the in-situ pumps were used to push the ice pigs. Therefore the downtime on each pipe was just a few minutes to insert each pig. At Site 1, the wet well pumps were insufficiently rated, so a mobile booster pump was used to boost the site's mains water supply.

80