The mission

In March 2015, the State Government of Rajasthan announced a scheme that aimed at strengthening the supply of safe drinking water to 3.5 million rural population from the districts of Hanumangarh, Sri Ganganagar and Bikaner. For nearly 25-30 years, these rural areas were being fed water from diggi based water treatment and supply system which were operated by the Public Health Engineering Department of the State (PHED). Over the years, as these infrastructures aged, they became non-functional and redundant. The slow sand filters used in these treatment plants, gradually, failed to cater to the needs of a growing population. Therefore, the State authorities felt the need to upgrade the existing water treatment systems so that safe drinking water could be supplied to the public. In 2016, the PHED asked SUEZ to design, build and operate 150 UCD. These 150 units, which are now built and commissioned over a period of two years, have a production capacity ranging between 500 m3/day to 3,000 m3/day.

These sites, selected for the upgrade and renovation of plants, were all rural, and, in many cases, remote and close to the international border deep inside the desert, without access roads. The plants must be designed and built in a way that makes day-to-day activities easier for future operators, who may or may not be as skilled. Additionally, the power supply in these regions is not continuous and, often, unpredictable, which could, in turn, disrupt the functioning of the plants, making water supply unreliable and ultimately disappointing the residents of the area.

SUEZ also proposed to introduce a range of digital solutions dedicated to effective and easy management of the assets and operation for the future. The objective was to develop an Asset Inventory Management System (AIMS), a centralized web portal, to manage treatment plants and utilities.

Our Solution

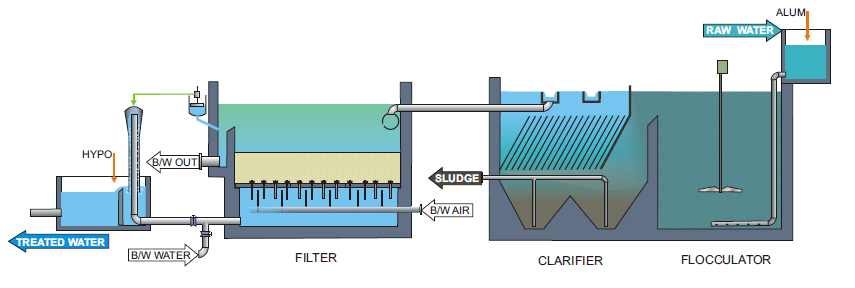

Understanding the limitations of the region, the technology that was chosen for the WTPs was modern and rugged. New false-floor Aquazur Rapid Gravity Filters (RGF) were used to treat the high turbidity waters having algal growth in diggis to produce good quality safe drinking water.

The technology used in this project has features that were unique to the requirements of the project:

- Only 150-180 w flocculation energy is needed for the treatment process. In case of drive failure, a hydraulic mixing energy system is provided to assist the flocculation process.

- The 3 MLD WTPs uses hydraulic flocculation, hence no energy or drive is used during the water treatment cycle. Only filter backwash uses electrical power once in a few days.

- Compact integrated design is provided for easy operation and maintenance by a single local operator. All plant operational controls are within 3-5 meters inside the plant room.

- The treatment plant is designed in a way that it can be operated by personnel with lesser skill.

- Aquazur filter backwash is done with scouring air to reduce backwash water consumption. Waste backwash water is recycled to conserve the water. Filters are designed to run for a week (8 hours per day), without backwash, providing flexibility in O&M.

- Aquazur filter backwash has a false floor for hydraulic self-balancing design that gives 100% media cleaning to maintain full suspended solids capturing capacity.

- Large size high-quality quartz filter media is provided to reduce media losses over years of operation.

- Aquazur filters use air siphon flow regulation automation system with no maintenance or power needs.

The Asset Inventory Management System was successfully integrated facilitating easy access to all data along with photos, maps, and videos etc. of all WTPs. Geolocation of all schemes situated in different locations is made available on the map.

The Result

The long-term vision of the state to provide safe drinking water to 3.5 million rural population has been met with the implementation of these projects. All the schemes under the project are commissioned and water production has started from these plants. This project has successfully reinforced SUEZ Group's commitment to developing resilient and sustainable water supply system, especially for vulnerable population who are devoid of safe drinking water. The local communities are pleased with the quality of water. Many villagers expressed deep satisfaction and gratitude for providing the schemes.