Softening of groundwater without chemistry

The pilot test in Juelsminde main objective is to remove the amount of the hardness that cause scaling in water heating system.

The scaling potential hardness that shall be removed in softening processes is different from a technology to another. In water softening technologies design and operation, it’s recommended to reach a CCPP at 90 °C below 0.6 mmol/L to avoid extensive lime scaling.

Pilot study objectives:

- Quantify scaling capacity of Juelsminde water drinking water resources

- Demonstrate the effectiveness of the technology

- Evaluate operating conditions

- Determine energy consumption

- Check limiting factors

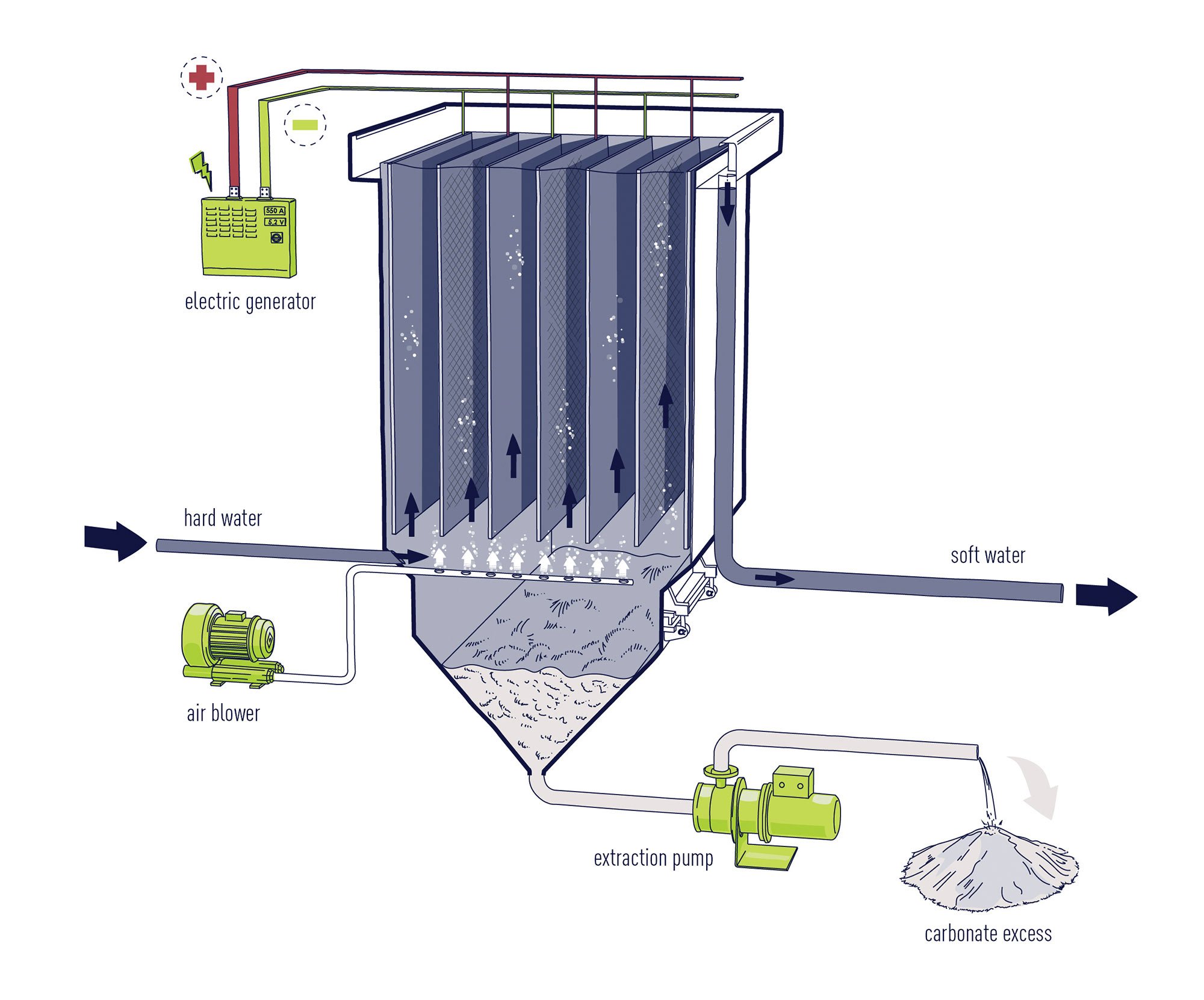

Electro-physic water softening process

In Juelsminde waterworks, we have decided to implement SUEZ ERCA2 pilot plant which targets reducing the water hardness from 22 to 15 odH.

The Erca2 pilot plant consists of:

- A reactor of 12 liters, stainless steel 316L reactor electrodes

- An electric generator (15V-10A) and connections

- Blowers and pipes

- Raw water pneumatic pump and flow meter

- A raw water 250 L tank

- Miscellaneous laboratory equipment for analysis: pH, TH, THCA, TAC conductivity

Equipment construction materials are high quality materials:

- Stainless steel range: 316 L and 304 L

- Titanium Ti 40 grade 2

- Iridium or Platine.

ERCA² process in a nutshell

If the water between these electrodes is mixed, the ions H3O+ and OH- neutralize each other and the electrolysis would produce hydrogen and oxygen. However, if a separation is realized with a laminar flow close to the cathode, OH- ions will convert bicarbonate into carbonate which in turn will precipitate with calcium.

The ERCA2 electro-physic technology regulates its action with the raw water flowrate. Removal efficiency is continuously measured with a double conductivity captor on the raw and treated water at the same time. The system is not concerned by other parameters such as turbidity or pesticides, but it can remove heavy metals (Ni – Al – Zn …).

Proven and reliable technology for water softening

The ERCA2 process has the specific and unique (patented) advantage of being a chemical - physical process which produces treated water for human consumption. Other advantages of the process are:

- Secured a protected water quality

- Automatic process

- Automatic scale extraction

- Continuous measurement for efficiency control

- Do not require the use of harmful chemicals

- Treated water is free from microbial pollutants

- Annual preventive maintenance for equipment control

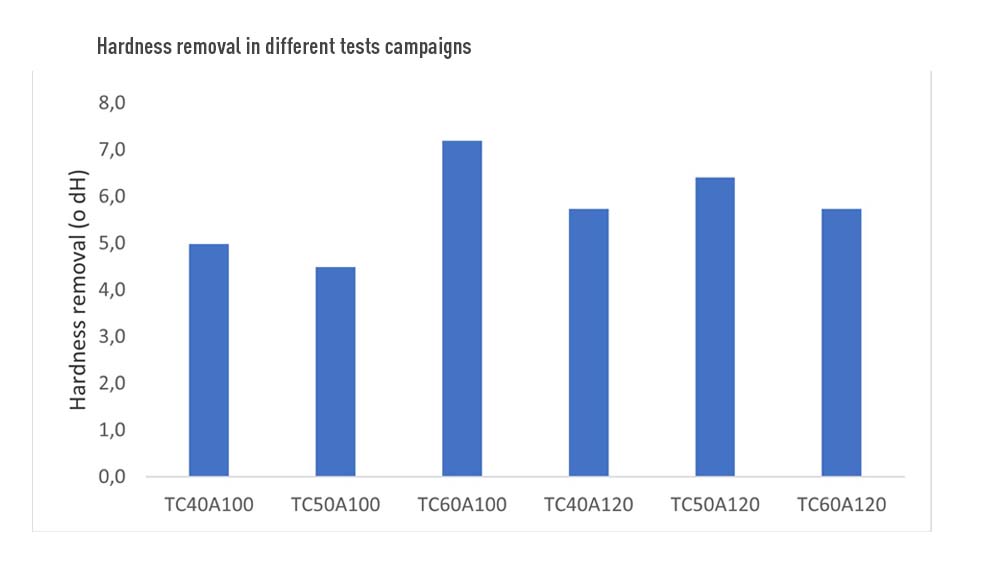

We could see all benefits of ERCA2 technology in Juelsimde and we were also able to achieve the target hardness of 6.8 °dH in hardness removal (visible red line in the picture below).

Global references

Contact our expert

If you have any questions or would like to know more, send email to: