Reducing water hardness with highly efficient softening technology

There could be many different softening solutions implemented to soften hard water in Stokkemark but nanofiltration is the best suited technology for this type of drinking water plant.

Nanofiltration is sustainable for smaller types of plants, it can provide much better water quality and reduce water hardness up to 90%, reduce DMS concentration up to 20%. Nanofiltration is also efficient in reducing bacteria and viruses, colors, odors and other water pollutions.

Nanofiltration is sustainable for smaller types of plants, it can provide much better water quality and reduce water hardness up to 90%, reduce DMS concentration up to 20%. Nanofiltration is also efficient in reducing bacteria and viruses, colors, odors and other water pollutions.

Nanofiltration membranes used in a drinking water softening

Decarbonation by membrane filtration, known as Softazur M, uses nanofiltration or low-pressure reverse osmosis membranes to retain different materials without adding any reagent.

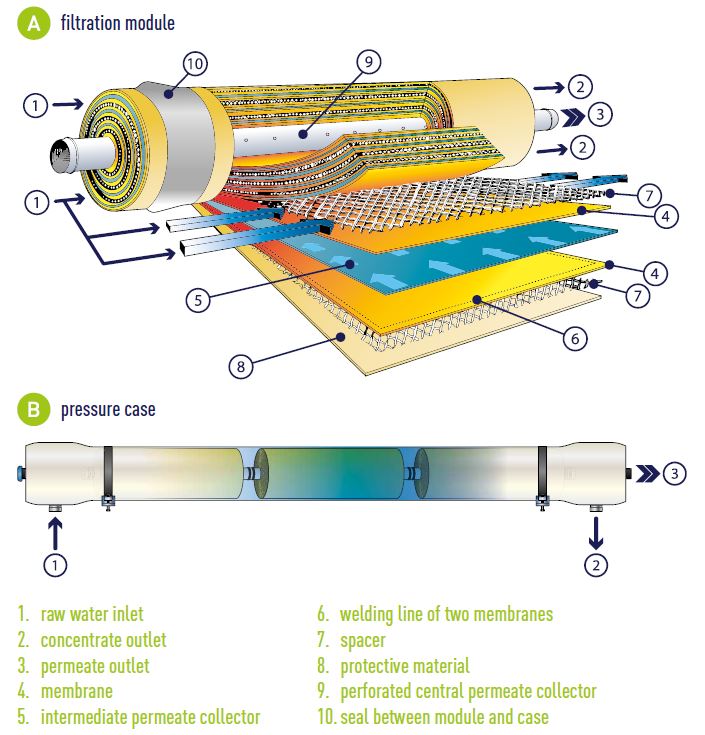

Spiral wound membranes

Originally designed for water desalination, spiral wound membranes are now used in a variety of applications including in the dairy industry and drinking water softening, in manufacturing products, for high purity water and at high temperature and extreme pH conditions.

SUEZ’s spiral wound membrane elements cross the spectrum of membrane including reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF), and microfiltration (MF) with plenty SUEZ references around the world.

SUEZ’s spiral wound membrane elements cross the spectrum of membrane including reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF), and microfiltration (MF) with plenty SUEZ references around the world.

Softazur M solution and nanofiltration membrane technology in a nutshell

Nanofiltration membranes are thin, semi-permeable solid media, which retain solids larger than a nanometer in size, bacteria and viruses as well as multivalent ions (including calcium and magnesium responsible for water hardness).

Image Generic

Image Generic

Reducing water hardness up to 90% by nanofiltration

Nanofiltration by membranes is solution with the highest rate of water softening that can reduce water hardness up to 90%.

Nanofiltration installed in Stokkemark drinking water plant was our pilot plant. We were able to reduce water hardness from 20°dH to 5.7°dH with a plant capacity of 220 liter per hour.

Nanofiltration installed in Stokkemark drinking water plant was our pilot plant. We were able to reduce water hardness from 20°dH to 5.7°dH with a plant capacity of 220 liter per hour.

Contact our expert

If you have any questions or would like to know more, send email to:

SUEZ in Danemark

SUEZ in Danemark